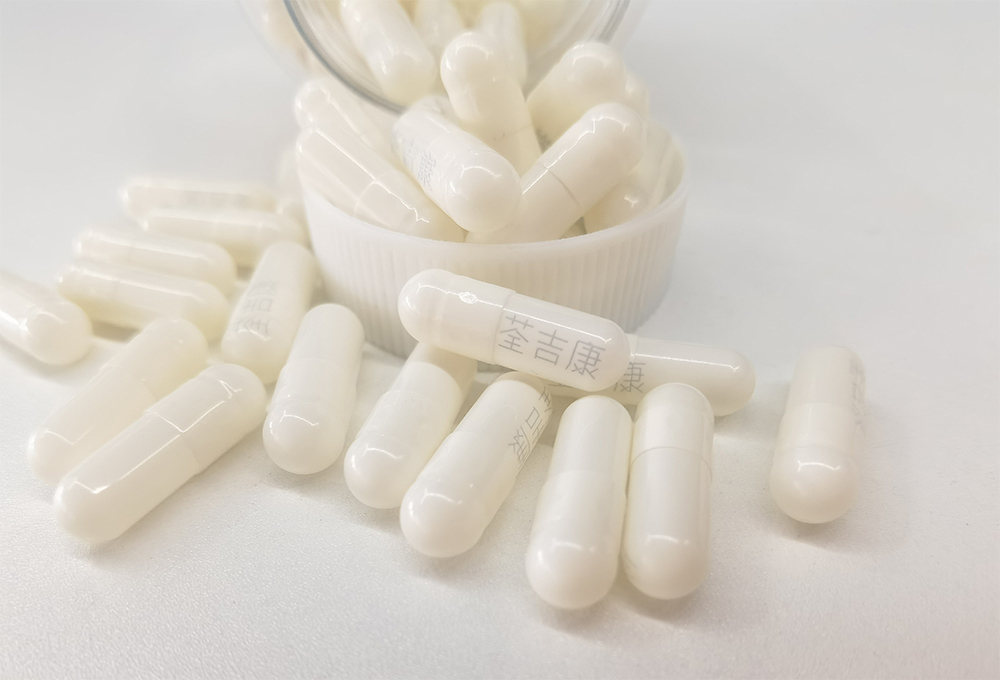

The plant capsule is a coat that wraps the drug, the purpose is to make the drug easier to take, to achieve the best effect.

In the practical application of plant capsules, pharmaceutical companies generally print logos on the surface of capsules, such as trademark letters, trademark names or drug names, in order to facilitate product identification, protect their own brands and prevent counterfeiting.

The marking capsule generally adopts the traditional ink inkjet process, and the marking process needs to use food grade ink that meets the standard. This method has obvious limitations, many consumables, marks are easy to erase, and food grade inks are expensive, and waste cannot be avoided during the printing process, thus increasing pharmaceutical costs.

In the research and development process, Tsuen Jikang found that laser marking technology can be applied to the identification printing of plant capsules. Laser marking technology is a non-contact marking technology, which can be marked with high precision and high definition on the surface of various materials.

Plant capsules belong to the field of medicine, requiring clear marking, wear-resistant, and high requirements for the fine degree of the marking machine. The capsule is small, there are 6 specifications (6 sizes) commonly used in the world, and there are difficulties in positioning and sanitary treatment. In order to solve these problems, experts and technicians repeatedly tried different laser marking processes, and targeted modifications to the equipment, and finally successfully broke through not long ago.

Automatic capsule laser marking machine can print more than 60,000 pieces per hour, marking clear, wear-resistant, not easy to fall off; Compared with the traditional ink inkjet process, marking does not require any consumables, which is not only green, but also reduces the cost.

It works by relying on laser energy to break the bonds between atoms and molecules, allowing them to vaporize or evaporate into small molecules, a process called "photoerosion" effect. At the same time, the process is small focus spot, the impact on the processing heat affected zone is very subtle, and smoke-free, pollution-free.

Technological innovation is the cornerstone of the long-term development of science and technology enterprises, Tsuen Jikang will continue to increase investment in scientific and technological innovation, master the core technology of the industry, enhance the core competition of enterprises, and accumulate strength for the future development of enterprises.